Our middle-market company enables our customers to benefit from the flexibility and responsiveness of a small to medium-size company,

while relying on the structure, stability and methodologies of a large company focused on:

Our continuous improvement approach ensures repetition and constant reliability of our production and services

Also our experience, expertise and the commitment of DEFI GROUP employees enable us to reach a quality level and logistic results that are very high.

The evolution of our sales turnover distribution has for several years reflected this clearly stated desire to minimise risk concentration.

6

520

74 M€

99 %

84 pts

31/40

Our growth target has been set at 35/40, with the aim of recruiting women in the maintenance technician and toolmaker professions.

5/10

Our objective is to reach 7/10 by giving priority to recruiting women to our management and executive committee positions.

The pragmatism of our 500 employees along with our machine fleet with a large power range enables us to accompany you in the industrial upscaling of your projects, from design to manufacturing:

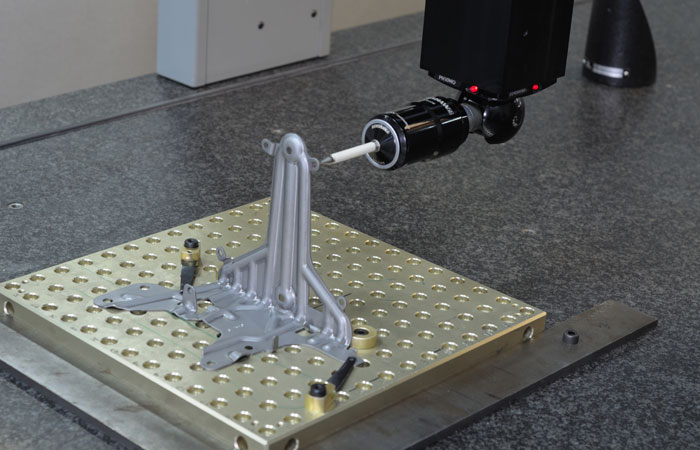

In order to meet the most demanding quality requirements, all our businesses are certified EN 9100 and/or IATF.

DEFI GROUP received in 2020 the EcoVadis silver medal for its CSR (Corporate Social Responsibility) performance. The objective of the EcoVadis CSR assessment methodology is to determine the quality of a company's CSR management system through its policies, actions and results. The assessment covers 21 points grouped into 4 themes: Environment, Social & Human Rights, Ethics and Responsible Purchasing. It is steered by a scientific committee, made up of CSR and supply chain experts, to ensure independent and reliable CSR assessments.

DEFI GROUP is also a member United Nations Global Compact.

Discover our (COP) 2021 document in the "Downloads" section below.

DEFI GROUP strives to propose a business model based on ethics, sharing, mutual respect and is committed to sustainable development and respect for the environment.

Faced with the urgency of the climate challenge, DEFI GROUP is leading an ambitious decarbonisation policy in order to contribute to the transition to a carbon-neutral industry by 2050. DEFI GROUP thus wishes to be a player in the energy transition and is committed to limiting the environmental impact of its activities, by recovering its waste, reducing its energy consumption, preserving resources and seeking to reduce its carbon footprint on all scopes (1, 2 and 3). This commitment to increasing its energy performance translates into :

Discover the implementation of our commitments through our CSR policy in the "Downloads" section below.

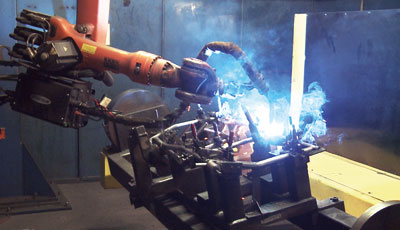

DEFI GROUP, winner of the french industrial investment acceleration fund As part of the deployment of the “France Relance” plan presented by the government, the prefect of the Île-de-France region, the prefect of Paris, Marc Guillaume, and the president of the Regional Council, Valérie Pécresse, announced 19 news regional companies winners of the industrial investment acceleration fund in the territories. These 19 new projects represent 9 million euros in subsidies mobilized by France Relance for a total of 75.6 million euros in productive investments across the region. They will enable the companies concerned to diversify their activity, to modernize their manufacturing processes and thus to perpetuate their presence in Île-de-France with the creation of more than 600 jobs. Among the winners, DEFI GROUP’s project was selected by the Seine-et-Marne region. This fund will support the company in its future investments in robotization and automation of its production processes. These new resources will in particular make it possible to gain in competitiveness in the current requests for quotation, relating to the growth markets of electricity and hybridization.

DEFI GROUP is an independent family-owned french company, created in 1957, specialized in metal components processing. Located on 6 production plants in Europe, DEFI GROUP became over the decades a group at the international level. With our 500 employees and our expanded diversified machinery equipment, DEFI GROUP generates a 70 million euro turnover.